Planer & Jointer Knife Quality

Planer & Jointer Knife Quality

Planer & Jointer Knife Quality

Titan Planer & Jointer Knife Quality

Best Quality - Great Price! |

| |

| Not all tools are created the same and the same goes for jointer and planer knives. Obviously you want to consider quality as well as price when deciding which knives to buy. Many of our online competitors only offer a vague description and a blurry photo; hoping you won't ask too many questions and just trust they will work out. We confidently guarantee our knives 100% and you will find our prices and in stock selection hard to beat! We produce knives using the finest grades of steel which are triple temper hardened and ground to a fine close tolerance finish. | |

Features to consider when comparing knives: | ||

| Titan Knife (US)

| THEM

|

Grade of Steel: | ||

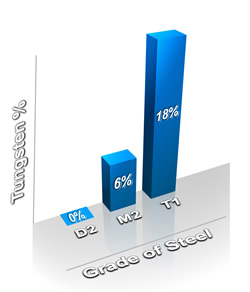

|  | Titan planer and jointer knife sets are made from high grade T1-High Speed Steel. Many competitors sell low cost knives made from sub-grade M2-HSS or the even lower grade D2 high carbon steel. Tungsten is the key ingredient in our planer knives. True T1-HSS contains 18% tungsten (18%W) allowing them to withstand cutting temperatures up to 1300 degrees fahrenheit without the temper hardness being affected. Tungsten has the highest melting point, (6,192 degrees fahrenheit) and the highest tensile strength of any element which is why it is used as the filament in light bulbs as well as for saw tips. Our T1-HSS planer knives have 3 times (300%) more Tungsten than the best grade of M2-HSS on the market while D2 grade steel does not contain any Tungsten. We chose to make our planer knives from costly T1-HSS grade because of its long tool life and heat-dulling resistance resulting in our T1 planer knives wearing longer and resisting dulling much longer than those made of M2 or D2. |

| ||

Grinding Finish: | ||

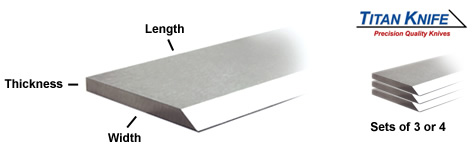

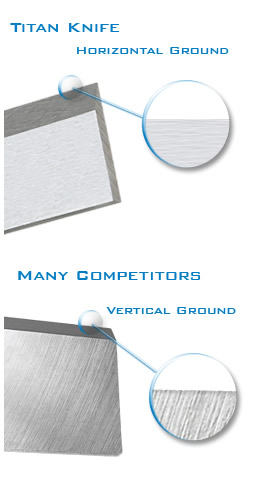

| Our knives are held to strict manufacturing process controls which includes holding tight tolerances on the knife thickness, width, length, and bow. We also surface grind the planer knives using Horizontal grinders to avoid scratches on the cutting edge resulting in a smoother wood finish and stronger cutting edge.

Many competitors use Vertical grinding machines that allow the knives to be ground faster but leave grinding marks on the face of the knives which micro-serrate the cutting edge. See the photos' to the right and the enlarged view of the cutting edge of our and our competitors knives. Many experienced woodworkers will only use knives with a horizontal finish grind in order to achieve the smoothest wood finish. |  |

| ||

Hardness: | ||

|

| The heat treating process is critical to knife performance and strength. We salt bath heat treat, triple temper and stress relieve each knife for superior through hardness and consistency. By using this process and since our knives are made from T1-HSS; we are able to reach a higher hardness than D2 or M2 knives without sacrificing strength of the steel. Our T1-HSS planer knives are hardened to 63-65 Rockwell C for extended tool life when cutting either soft or hard woods. |

| ||

Balance: | ||

|

| The knives in each set come balanced to within 0.1 grams (1/10 the weight of a dollar bill) to maintain the closest tolerances and reduce cutter-head vibrations which affect the surface finish and machine wear. Each knife is wire EDM cut to length to maintain close length tolerance and end squareness and packaged in a protective sleeve to avoid edge damage and to reduce the risk of getting cut when handling. |